LONG Dipping Technology-World Recognized

Author: Syu, Jyun-Yang | ChinaTimes News – 2012/10/8 5:30 A.M.

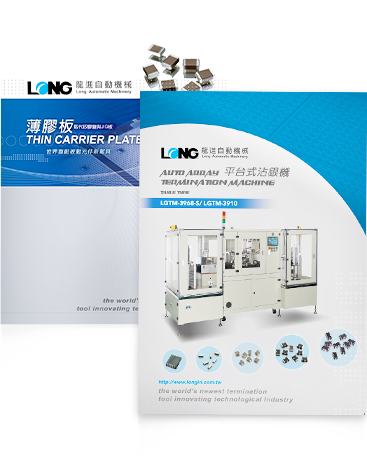

LONG Automatic Machinery Company Limited specializes in researching, designing and manufacturing automatic dipping machines for passive components. The company develops its product lines mainly on chip, core, and SMD such as termination dipping and array dipping. This innovation is successful and allows the company to be the top choice in the world. TCP(Thin Carrier Plate)& ATCP(Array TCP) carrier products has been 7 years since it was invented. It contributes to 50% growth rate every year for the company. The market of the products is not only adopted in Taiwan, but also expands to Europe, America, Japan, Korea, China, Southeast Asia, and Russia, from which companies all affirm the solution of TCP dipping and adopt this solution intensively. This year(2012) is the 25th anniversary of LONG company. In order to response to the growing business, the company is now planning to expand its capacity.

Lin, Sen-Song, the general manager of LONG Automatic Machinery Company Limited, said, it is the opportunity to replace the old carrier plates with new carrier plates and new production procedures, which is an inevitable trend in the world. Also, it is also one of the strategies to improve the competitiveness. The company developed and promotes its “Thin Carrier Plate” dipping procedure, which is already the best choice among all other solutions in the quality provided of chip dipping. Furthermore, in terms of cost, the waste of the consumable products is lower by 40% than other solutions. In sum, it is a successful achievement in eras to gradually replace past dipping solutions, such as carrier plate and JIG plate, after it released. Many worldwide passive components companies has replaced carrier plate and JIG plate procedures with thin carrier plate procedure, in improving quality, reducing consumable costs and saving human resources, to improve competitiveness in the world.

With respect to the research and design on smaller chip dipping procedures, the company has developed TCP and tooling for 01005 (in inch, 0402 in mm). This can be applied on the same dipping machines owned by clients with only change of TCP and tooling for 01005 chip dipping procedure. Moreover, the new type of TCP has improved vacuum attachment, increasing chip loading rates, dipping quality and production efficiency. Take 01005(in inch) chips dipping for instance, the previous dipping quantity was 13,776 chips per piece, it is planned to increase to 18,228 chips per piece[1]. Furthermore, LONG plans to increase the 0603(in inch) chips dipping quantity per piece from 13,776 chips up to 25,888 chips[2]. This development greatly reducing the cost of consumables and human resource.

In terms of Array dipping, the company focuses on improving positioning precision, automation, and fine(0506,0508, in inch) Array chip dipping with automatic production lines by single-side dipping and double-side dipping. Apart from this, the company plans to expand its business into special chip dipping such as wound inductor dipping, diode dipping, and piezoelectricity. With the continuous research of the company, it is expected to reach a more prosperous future. Company website:www.longin.com.tw。

[1] Now LONG has successfully achieved 18,128 chips per piece. (2014)

[2]25,376 chips per piece is under development. (2014)

Translated by Lin, Yu-Min

Article source:https://tw.news.yahoo.com/%E9%BE%8D%E9%80%B2%E5%A1%97%E4%BD%88%E6%8A%80%E8%A1%93-%E7%8D%A8%E6%AD%A5%E5%85%A8%E7%90%83-213000266--finance.html